Infrastructure

Omnitech has been built engineering excellence, crafted through unstinted dedication to quality, innovation and a constant objectives to serve the global market. The Company was started with clear objectives of customer’s requirement of quality at an outstanding value.

- ISO 9001: 2015, ISO 14001:2015, ISO 45001:2018 & IATF 16949 from TUV-SUD.

- Equipped with 74 CNC Machines, 47 VMC Machines, 4 CNC Grinding Machines , 4 Gear Shaper Machines & 42 Conventional Machines with extended capacity of 171 CNC Machines.

- Material handlings of – Stainless Steel 34%, Carbon Steel 36% & Non Ferrous 30%.

- Export Business – 91%.

- Total Employees – 620+.

Manufacturing areas

Skilled employee dedicated to development. Modern machines for better quality products. Scheduled quality checks to maintain quality benchmarks. And resources for FAIR & PPAP.

Very ambient work place along with canteen & recreation facility.

Dust-free assembly area to ensure manufacturing of products with quality benchmarks

Production Machines

Our manufacturing area is Equipped with 74 CNC machines of turning center and vertical machining center, 4 CNC grinding machines , 4 Gear shaper machines & 42 conventional machines with extended capacity of 171 CNC machines.

We follow Quality Technique

(7QC Tools)

1. 8D

2. Why-Why Analysis

3. APQP

4. PFMEA

5. SPC

6. MSA

7. PARETO Analysis

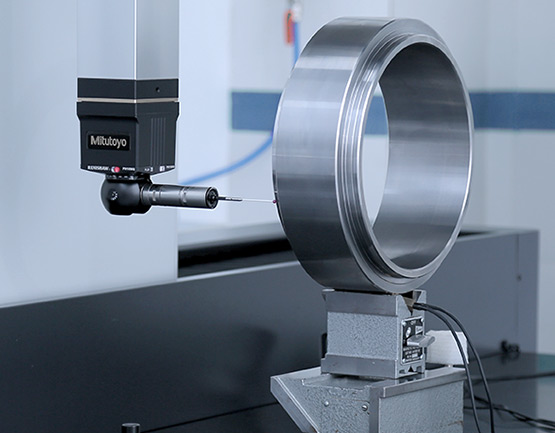

Quality Testing & Measuring Facility

Omnitech ensures manufacturing products tested with latest technology and process to meet quality benchmarks.

Assembly Area

We have a dedicated assembly area for our sub-assembly process with a skilled and qualified team.

warehousing facility in USA and Europe.