Quality Policy

We at Omnitech Engineering Pvt. Ltd. are committed to meet customer’s requirements through continual improvement of our quality management systems. We shall sustain organizational excellence through visionary leadership and innovative efforts.

We are Certified with ISO 9001:2015, 14001:2015,

We are Certified with ISO 9001:2015, 14001:2015,

45001:2018, IATF 16949

by TUV SUD, South Asia

View ISO 9001 : 2015 Certificate

View ISO 14001 : 2015 Certificate

View ISO 45001 : 2018 Certificate

View IATF 16949 Certificate

View AS9100:2016 Certificate

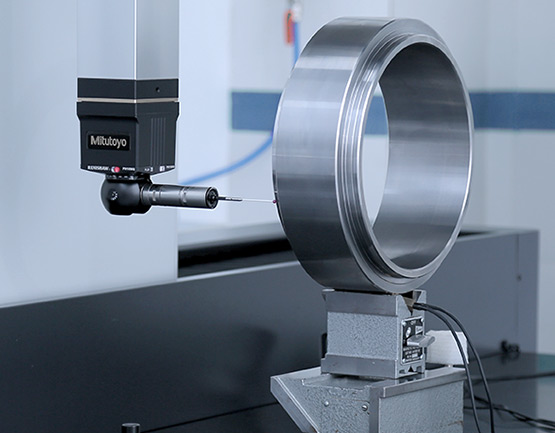

Quality Assurance

Receiving inspection of purchased products

- Chemical and Physical testing of each Raw Material as per control plan with reference to Raw Material Standard of purchased bright bars, forgings, castings & other assembly spares.

- Dimensional inspection of purchased bright bars, forgings, castings and other assembly spares.

In-process Inspection

- Set up approval of manufacturing process as per defined control plan with reference to drawing prepared.

- In-process inspection as per defined control plan with reference to drawings prepared on hourly basis.

- Separate identification and traceability of non-conforming products at In-process stage.

Final Inspection

- 100% Visual inspection of each lots produced as per defined plan with reference to visual defects like operation missing, rusts, blow holes, rough finishing, dent marks, tool marks and input material defects.

- Sampling dimensional inspection of all critical dimensions as per defined control plan with reference to drawing prepared.

- 100% dimensional inspection of major critical dimensions of small tolerances as per defined control plan with reference to drawing prepared.

- Separate identification and traceability of non-conforming products as final stage.

Pre-Dispatch Inspection

- Pre-dispatch inspection before deliver the products to customer as per their requirements along with inspection report and separate identification of inspected samples with reference to customer or internal drawing.